Innovative Applications of Laser Technology in Modern Manufacturing

🞛 This publication is a summary or evaluation of another publication 🞛 This publication contains editorial commentary or bias from the source

tech

- Click to Lock Slider

Revolutionizing the Factory Floor: Innovative Applications of Laser Technology in Modern Manufacturing

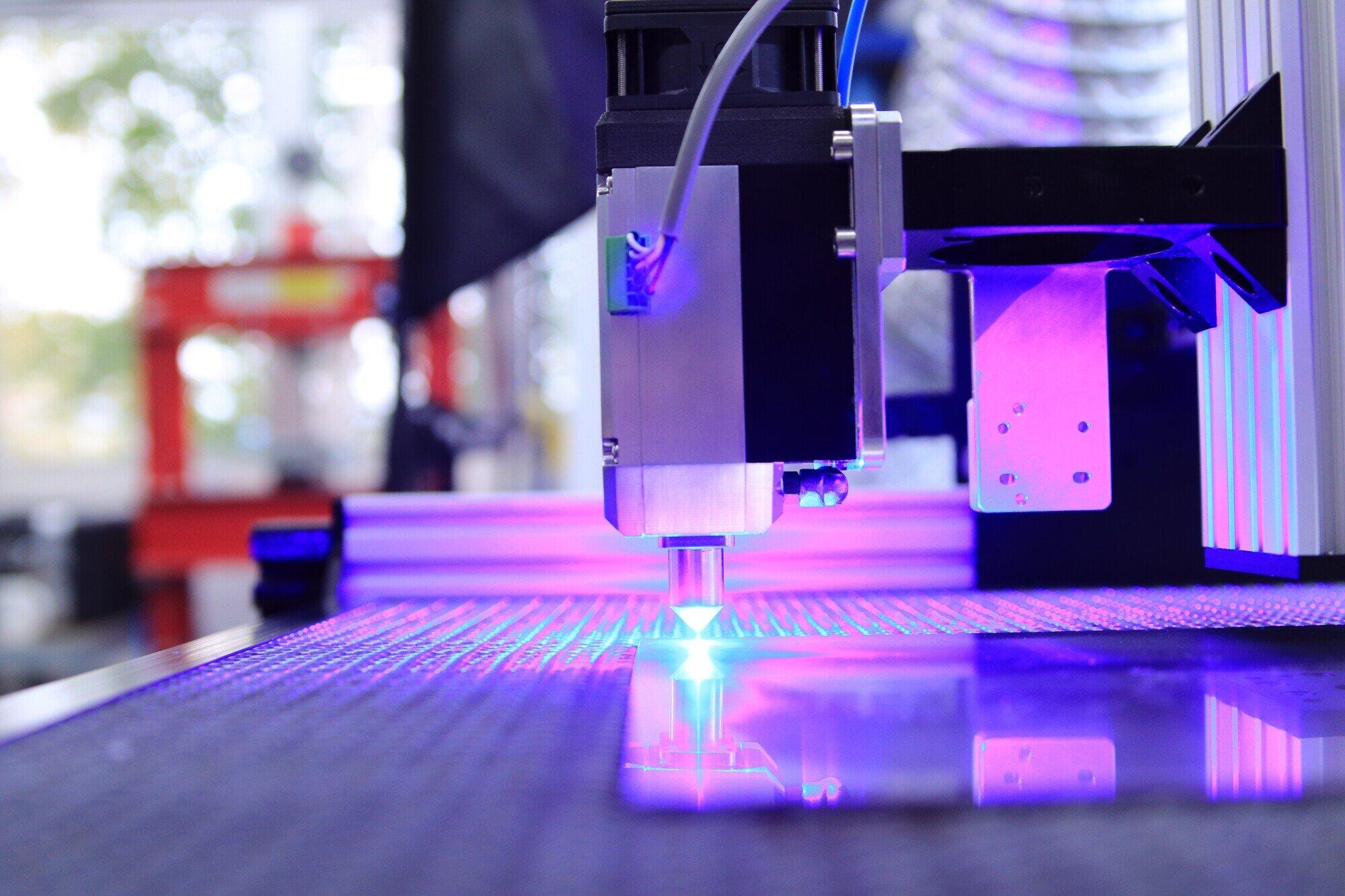

In the ever-evolving landscape of modern manufacturing, laser technology stands out as a transformative force, reshaping how industries produce everything from intricate electronic components to massive aerospace structures. Once confined to science fiction and basic cutting tasks, lasers have now permeated every corner of the production process, offering unparalleled precision, efficiency, and versatility. This surge in adoption is driven by advancements in laser systems, such as fiber lasers, CO2 lasers, and ultrafast lasers, which enable manufacturers to achieve feats that were previously unimaginable. As global markets demand faster turnaround times, higher quality, and sustainable practices, laser technology is not just an tool—it's a game-changer that's redefining the boundaries of what's possible in manufacturing.

At the heart of laser applications in manufacturing is laser cutting, a process that has revolutionized material processing across sectors. Unlike traditional mechanical cutting methods, which often involve blades or saws that wear down and generate significant waste, laser cutting uses a focused beam of light to slice through materials with pinpoint accuracy. This technique is particularly valuable in industries like automotive and aerospace, where components must meet exacting tolerances. For instance, in automobile production, lasers cut complex shapes into sheet metal for car bodies, reducing material waste by up to 30% compared to conventional methods. The precision of lasers minimizes errors, ensuring that parts fit together seamlessly during assembly. Moreover, the non-contact nature of laser cutting prevents tool degradation, leading to lower maintenance costs and longer operational lifespans for equipment.

Beyond cutting, laser welding has emerged as another cornerstone innovation, providing stronger, cleaner joins than traditional welding techniques. By concentrating intense heat in a small area, lasers can fuse metals, plastics, and even composites without the need for filler materials in many cases. This is especially beneficial in the electronics industry, where delicate circuit boards require welds that don't introduce contaminants or excess heat that could damage sensitive components. In the medical device sector, laser welding is used to assemble implants and surgical tools, ensuring sterile, high-strength bonds that withstand the rigors of human use. A notable example is the production of pacemakers, where lasers create hermetic seals that protect internal electronics from bodily fluids. The speed of laser welding—often completing joins in milliseconds—also boosts production rates, allowing manufacturers to scale operations without sacrificing quality.

Laser marking and engraving represent yet another innovative application, blending functionality with aesthetics in manufacturing. This process involves using lasers to etch permanent marks, barcodes, or designs onto surfaces, which is crucial for traceability and branding. In the consumer goods industry, lasers engrave serial numbers on smartphones and laptops, enabling efficient inventory tracking and anti-counterfeiting measures. Unlike ink-based marking, which can fade or smudge, laser engravings are durable and resistant to wear, making them ideal for harsh environments like oil and gas equipment or military hardware. Furthermore, the customization potential is immense; manufacturers can personalize products on-the-fly, catering to the growing demand for bespoke items in markets like fashion and jewelry. This flexibility not only enhances product value but also streamlines supply chains by reducing the need for separate labeling processes.

One of the most exciting frontiers of laser technology in manufacturing is additive manufacturing, commonly known as 3D printing. Lasers play a pivotal role in processes like selective laser sintering (SLS) and selective laser melting (SLM), where they fuse powdered materials layer by layer to build complex geometries. This innovation is transforming industries that require lightweight, high-performance parts, such as aerospace and defense. For example, companies like Boeing and Airbus use laser-based 3D printing to create turbine blades and structural components that are lighter and more fuel-efficient than those made with traditional forging. The ability to produce intricate internal structures, impossible with subtractive methods, opens doors to optimized designs that reduce weight without compromising strength. In the biomedical field, lasers enable the printing of custom prosthetics and implants tailored to individual patients, improving outcomes and reducing recovery times.

Laser cladding and surface treatment applications further illustrate the technology's versatility. In heavy industries like mining and energy, lasers are used to apply protective coatings to worn parts, extending their service life and reducing downtime. This process involves melting a layer of material onto a substrate, creating a metallurgically bonded surface that's resistant to corrosion, abrasion, or high temperatures. For instance, in oil rigs, laser cladding repairs drill bits on-site, minimizing the need for costly replacements. Similarly, in the automotive sector, lasers harden engine components, enhancing durability and performance. These treatments not only improve product longevity but also contribute to sustainability by promoting repair over replacement, aligning with global efforts to reduce industrial waste.

The benefits of integrating laser technology into manufacturing extend far beyond individual processes. Overall, lasers enhance efficiency by automating tasks that once required manual labor, thereby reducing human error and improving workplace safety. Their energy efficiency—focusing power precisely where needed—lowers operational costs and environmental impact, as they produce less scrap and emissions than mechanical alternatives. In an era of Industry 4.0, lasers integrate seamlessly with robotics, AI, and IoT systems, enabling smart factories where real-time data optimizes laser parameters for maximum output. For small and medium-sized enterprises (SMEs), affordable laser systems democratize access to advanced manufacturing, leveling the playing field against larger corporations.

Looking ahead, the future of laser technology in manufacturing promises even greater innovations. Developments in ultrafast lasers, which operate in femtoseconds, allow for micro-machining at the nanoscale, opening possibilities in semiconductor production and nanotechnology. Hybrid systems combining lasers with other technologies, like plasma or waterjets, are expanding capabilities for processing exotic materials such as advanced composites and ceramics. As sustainability becomes a priority, green laser technologies that minimize energy use and hazardous byproducts are gaining traction. Challenges remain, including the high initial investment and the need for skilled operators, but ongoing research and training programs are addressing these hurdles.

In conclusion, laser technology is not merely enhancing modern manufacturing—it's fundamentally reinventing it. From precision cutting and welding to additive processes and surface enhancements, lasers deliver the accuracy, speed, and adaptability that today's competitive markets demand. As industries continue to innovate, the beam of the laser will undoubtedly illuminate new paths toward efficiency, customization, and sustainability, ensuring that manufacturing remains at the forefront of technological progress. For manufacturers willing to embrace this light-speed revolution, the rewards are boundless, promising a brighter, more efficient future for production worldwide.

Read the Full Impacts Article at:

[ https://techbullion.com/innovative-applications-of-laser-technology-in-modern-manufacturing/ ]

Similar Media and Entertainment Publications

[ Last Thursday ]: Forbes

Category: Science and Technology

Category: Science and Technology

[ Thu, Jun 05th ]: IOL

Category: Science and Technology

Category: Science and Technology